A Company You Can Trust

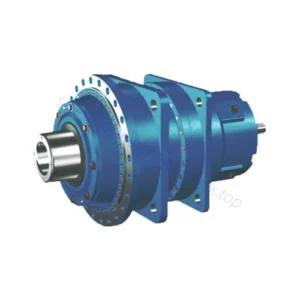

Planetary Gearbox

WHAT IS A PLANETARY GEARBOX?

A planetary gearbox is one in which the input and output shafts are aligned. Planetary gearboxes transmit maximum torque in the most compact form known as torque density.

The acceleration hub of a bicycle is an excellent example of a planetary wheel mechanism: have you ever wondered how to get so much power and capability in such a small hub? A one-stage planetary gear system is used for three-speed hubs, and five-speed hubs, two stages are used.

Mathematically, the smallest reduction ratio is 3:1, and the largest is 10:1. At reduction ratios less than 3, the sun gear becomes too large relative to the planet gears. The sun gear becomes too tiny when the ratio is greater than 10, and torque drops.

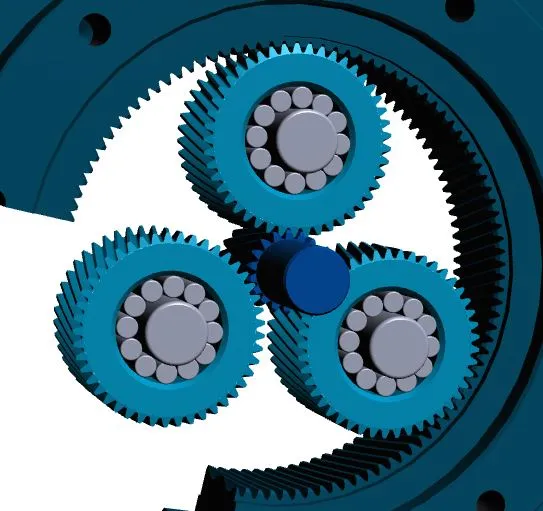

WHY IS IT NAMED A PLANETARY GEARBOX?

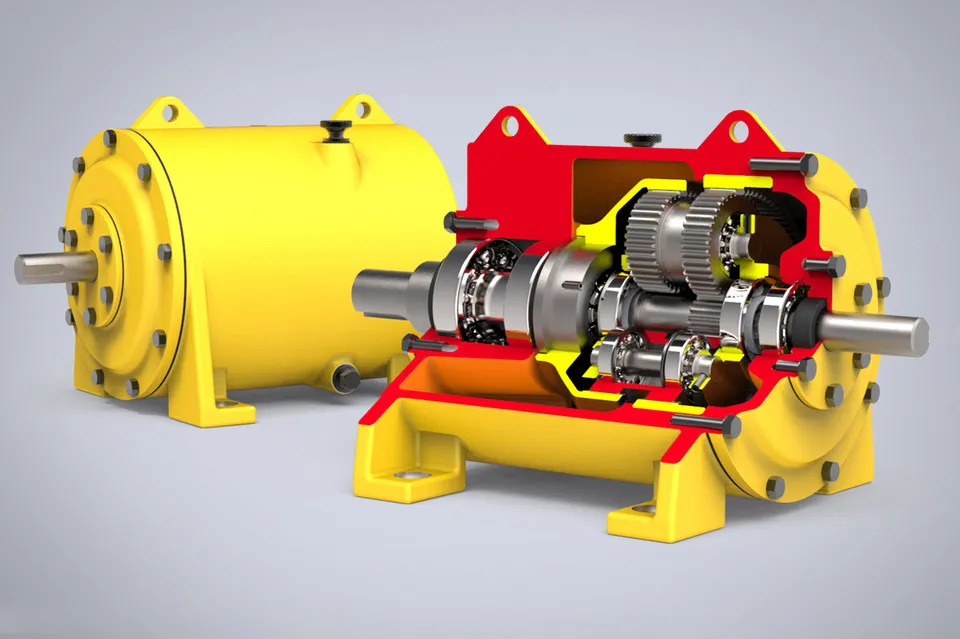

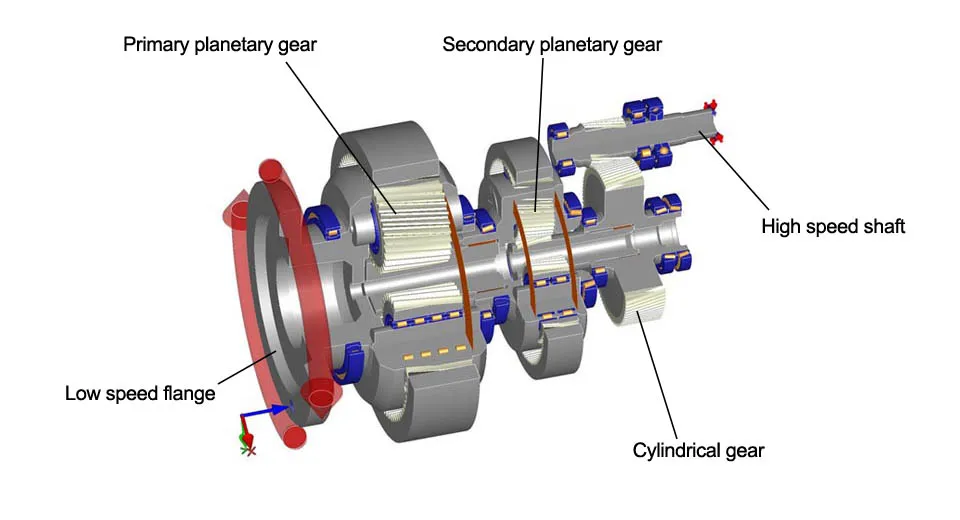

Planetary gearboxes get their name from how different gears move together. In a planetary gearbox, we see sun (solar) gear, satellite (ring) gear, and two or more planetary gears. Typically, the sun gear is driven, moving the planet gears locked in the planet carrier and forming the output shaft. The satellite gear has a fixed position relative to the outside world. This looks similar to our planetary solar system, where the name comes from. Helpfully, ancient gear structures are widely used in astrology to map and track our celestial bodies. So it’s not a huge step.

In practice, we often speak from the perspective of industrial automation using planetary gearboxes.

WHERE IS THE PLANETARY GEARBOX USUALLY USED (IN THE TRANSMISSION)?

Where is the planetary gearbox usually used (in the transmission):

- In a robot to increase the torque

- In a printing press to reduce the speed of the rollers

- For precise positioning

- In a packaging machine for a reproducible products

Features of Planetary Gearboxes

Since the planetary gearbox contains multiple planetary gears, multiple teeth mesh simultaneously during operation. This power distribution ensures higher efficiency compared to other types of gears and therefore also allows for higher transmittable torque in a more compact design.

The gear ratio of the planetary gearbox is determined by the gear ratio between the ring gear and the sun gear. If the ring gear size remains the same, the gear ratio can be changed by changing the number of teeth on the sun and planet gears. The smaller the sun gear you choose, the larger the gear ratio. In the mathematical discussion, the lowest gear ratio is 3:1 and the largest is 10:1. At gear ratios less than 3, the sun gear becomes too large for the planet gears. The sun gear becomes too small, and torque decreases when the gear ratio exceeds 10. However, if higher gear ratios are required, multiple planetary gear sets can be arranged in succession in the same ring gear or in two fixed ring gears. Such constellations are then called multi-stage planetary gears. Planetary gearboxes are suitable for counterclockwise and clockwise rotation, as well as continuous, alternating and intermittent operation.

Choosing a Planetary Gearbox

When selecting a planetary gearbox for a particular application, it is essential to note the following.

- Features required: torque, backlash, ratio, etc., of the case should be considered.

- Environment: some environments may leave a device exposed to dust, dirt, or moisture, so it is essential to consider this property and choose a planetary gearbox with the proper protection.

- Space: planetary gearboxes are in different sizes; if there is a limited place available, then a more miniature planetary gearbox can be employed.

China Good quality Carton Packing CE Certification Tiller Agriculture Small Precision Planetary Gearbox automatic gearbox

China Standard Dxtl OEM Custom Made Stepper Motor Gear Speed Reducer Gearbox Planetary Reduction Gearbox gearbox definition

Product Description Planetary reducer is a widely used industrial product that can reduce the speed of the motor while increasing the output torque.Planetary reducer can be used as supporting parts for lifting, mining, transportation, construction and other...

China supplier Zoolern Free Fall Winches Zhp 6.27/6.29/6.31 Planetary Gearbox From China Manufacturer gearbox drive shaft

Product Description Elite free fall winches consist of integrated winch gearboxesand a free fall brake. The winch gearbox is based on a modular system. Key features Rope pull forces on the drum from 30 KN to 700 KN Rope speed up to 1,400 m/min Excellent load control...

Advantages of planetary gearboxes

Planetary gearboxes have coaxially aligned input and output shafts. This type of assembly means that the planetary gearbox is compact. They transmit high torque in a compact design with high torque density and low backlash. The simple design is an efficient and effective way of transferring power from the motor to the output. About 97% of the input energy is transferred as output. They allow for high gear ratios that allow for substantial reductions. They have decent stiffness and low noise. With better load distribution, they have a longer service life.

Application of planetary gearbox

Planetary gearboxes are widely used in industrial applications due to their numerous advantages. Planetary gears handle speed and torque conversion in electrical systems and machines. Planetary gearboxes can be connected to any type of motor such as servo, DC or stepper motors. Of course, the use of planetary gears is not limited to industrial applications, but can be found in many fields. Some application areas can be: